level measurement

Level Sensors for Hydrostatic Level Measurement

Level sensors and fill-level transmitters are specialized types of pressure sensors used for continuous level measurement in tanks, shafts, vessels, basins, or wells. The measurement is based on the hydrostatic principle: the weight of the liquid column above the sensor creates pressure, which is directly proportional to the fill height.

This pressure acts on the sensor’s measuring element and is converted into an analog electrical signal. The method is ideally suited for non-turbulent liquids and viscous media across a wide range of industrial applications.

Two Sensor Types for Different Applications

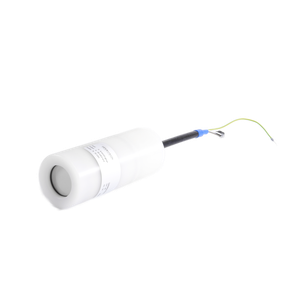

1. Submersible Probes – for Open Tanks

Submersible probes (also called level probes) are designed for open containers such as tanks, shafts, and reservoirs. The probe is lowered and fixed at the lowest point of the vessel. It measures

the hydrostatic pressure generated by the liquid column above. With the known fluid density, the system accurately calculates the current fill level.

2. Screw-in Probes – for Pressurized or Closed Systems

Screw-in level sensors are used in closed or pressurized systems. They are mounted at the bottom of the vessel and measure the static pressure at that point. This value directly correlates with

the liquid level, regardless of ambient pressure.

Suitable for Aggressive Media and Hazardous Areas

Both submersible and screw-in sensors are available in various versions. A wide selection of sensor technologies (e.g., stainless steel or ceramic cells), housing materials, cable types, and seal materials makes them suitable for use in aggressive media and explosive environments (e.g., with ATEX or IECEx certification).

Typical Applications:

- Drinking water and wastewater systems

- Storage of fuels and chemicals

- Food and beverage processing

- Environmental and process engineering

screw in level transmitters

separable submersible level transmitters

submersible level transmitters

We don’t offer alternatives — we pioneer technologies where no alternatives exist.